By: George Nenni, Vice President of Operations

Part I of this series explained the importance of defining your current reconditioning process. This time, we will look at how your perception of this process may be different from what is really happening.

Ask most dealers how many days it takes to get cars through reconditioning, and the answer is usually three, four, or five days. However, when dealers probe a bit more, they learn that it is actually around 10 or 12 days, creating a cascade of concerns.

Leaking Profits

First, there are carrying costs, often quoted around $32 to $40 per day (NCM and NADA respectively). At an average of $36 per day, with a turn of 50 cars per month, that’s a $9,000 monthly profit leak if reconditioning actually takes 10 days instead of five days. Most dealers would rather put $9,000 into good marketing and merchandising.

Poor Consumer Experience

There is also the issue of missing photos on the dealership’s website. Since many dealers grab inventory data from their DMS, enhancing it with photos, videos and descriptions from lot service companies like Dealer Specialties, the cars in reconditioning appear on the website with little information and no photos until they are ready for sale. This results in vehicle listings that appear outdated or neglected. Neither captures the attention of today’s Internet shoppers.

Lack of Accountability

Finally, if dealers don’t know where the bottlenecks are and who’s responsible, a vehicle’s days to market can’t improve. Is the body shop consistently waiting on cars from the service department, or vice versa? Do outside vendors take longer to complete the scheduled workflow? Maybe it’s time to make some inquiries and re-evaluate this process.

So, where to start?

Understand and Define the Process

First, dealers need visibility into how long vehicle reconditioning takes, or better yet, how long each step in the process takes. When considering steps, make sure to include ones that don’t involve actual reconditioning work, like getting manager approvals on ROs or waiting on parts.

Identify and Eliminate Bottlenecks

Once the steps are defined, look for bottlenecks and snuff them out when they appear. Keep in mind that while bottlenecks may not be completely removed, adjusting them can reduce the additional time each bottleneck currently adds to the process.

Reinforce Good Performance

Finally, don’t forget to consider incentives, recognition, and compensation. Set standards for what a good job looks like. Measure to those benchmarks, then recognize and reward staff or departments that outperform.

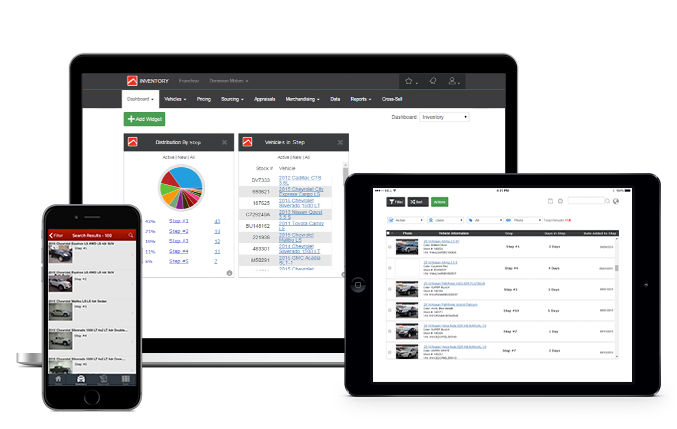

There are many ways to track the reconditioning process, but a web-based software solution- preferably a mobile app, is the best direction. Compare the price of the mobile app to the potential savings of reducing the number of days from vehicle acquisition to front-line ready. Then do the math. As the illustration above shows, this investment will have a very quick payback.

Stay tuned for Part III by subscribing to our blog today.